CNC Chip Load, Feeds, and Speeds

Greetings, fellow woodworkers. If you've recently jumped into CNC machining, and are at the entry- or hobby-level, you've probably heard "Chip Load" and "Feeds and Speeds" tossed around like sawdust in a windstorm. But what do they really mean? And how do you use them without turning your project into firewood or hurting your machine?

No worries, we're unpacking these CNC formulas in a way that's easy to learn, especially if you're a beginning CNC operator with some woodworking experience. We'll anchor it to the Onefinity Journeyman X-50, which I own and is an upper-range hobby machine. We'll use sample calculations, a simple graph, and cover some rookie mistakes to dodge (because we've all been there). Here's the point to keep in mind: these numbers? They're guidelines, not set in stone. You'll tweak them based on your machine and material. Let's dive in.

What Are Chip Load and Feeds and Speeds, Anyway?

Think of "Chip Load" as the size of the chunk your CNC bit grabs from the wood with each spin. It's measured in inches per tooth, how much material each flute (the cutting edge on your bit) removes per revolution. Too big a chunk, and your machine grumbles; too small, and you're just kicking up dust instead of chips.

Most manufacturers provide either Feeds and Speeds or Chip Load, with Feeds and Speeds being more common. I have a pair of simple calculators for both.

If your bit manufacturer does not provide Chip Load or Feeds and Speeds, it's not a problem. We'll just start at a conservative number for feed rate, like 60 inches per minute (IPM) and a mid-range spindle or router (we'll use spindle for simplicity going forward, but they are interchangeable for this discussion) RPM of 16,000 as inputs. You'll need to look at your bit to determine the number of cutting flutes, which is typically between 1 and 3, but can go as high as 8, where 2 is very common. With these numbers in mind, we can provide the inputs for the Chip Load formula, which is a very tiny number, typically measured in thousandths of an inch:

Chip Load = Feed Rate (IPM) × RPM × Number of Flutes

Chip Load = 60 * 16,000 × 2 = 0.001875 inches

"Feeds and Speeds" are the power duo behind Chip Load. "Feed Rate", or feed, is how fast your bit runs through the wood (in inches per minute, or IPM), and "Speed" is how fast your spindle spins (in revolutions per minute, or RPM). Together, they decide if your cut's smooth or if you're mistreating your bits or CNC, perhaps to the point of failure. Again, these are guidelines, so don't let that previous sentence stop you, it's just to let you know this is important.

The formula linking them is:

Feed Rate (IPM) = RPM × Chip Load × Number of Flutes

Simple, right? Well, sorta. The hitch is that it depends on your machine keeping up. A flimsy entry-level CNC might choke where the Onefinity Journeyman powers through, thanks to its solid build and zippy stepper motors. And there are plenty of Pro and Industrial machines that laugh at what a Onefinity can manage, but they probably know more about this formula and its nuances than I can ever convey here.

Why the Onefinity Journeyman

Before we crunch numbers, let's talk about why the Onefinity Journeyman is mentioned here. First off, it's my daily driver CNC. It's an upper-range hobby CNC, not industrial, but a big leap from those wobbly entry-level rigs, one of which I started with and still use occasionally. Its rigidity (how little it flexes under pressure) and stepper motors (the muscle moving the gantry) give it the guts to handle dense woods like maple without shaking apart. Compare that to a lesser machine with a palm router for a spindle, and you'll see why adjustments are key. The Onefinity can take on bolder cuts, but you've still got to respect its limits, and your bit's, too.

Please don't think I'm dismissing palm routers, since that is what I use on both of my CNCs. My entry-level CNC uses either a Bosch Colt or a DeWalt DWP600 palm router and my Onefinity Journeyman uses a Makita RT0701C palm router, with the option to upgrade to a variety of variable frequency device (VFD) spindles. I would like to have a spindle on my Onefinity, but the palm routers do the job at 1/4 to 1/2 the price and typically weigh less, as well. For an entry-level CNC, the lower weight hanging on the gantry makes a big difference, whereas the Journeyman has the strength to support a 3 HP (2.2 KW) spindle without an issue. The palm routers typically are rated at 1.25 HP.

Crunching the Numbers: Sample Calculations

Let's get practical with two Amana bits, both solid carbide upcut spirals (great for clearing chips in wood). We'll compare MDF (soft and dusty) and solid maple (a hardwood classic) on the Onefinity Journeyman. And before you think this is a pitch for Amana, I'm just mentioning them because the Chip Load specs for these two bits are readily available in a single PDF file at this link, which makes it easier to discuss the formulas.

In real life, I'm a fan of bits from Cadence Manufacturing and Design, and IDC Woodcraft. If you drop by Cadence (Cody) or IDC (Garrett), tell them I said "Hi". They are both great people and I've bought bits from them several times. They are both active on CNC Facebook forums, so they are very approachable and helpful. I have yet to see Amana, or anyone representing Amana, on a Facebook CNC forum.

Cody actually manufacturers bits at his own shop in Arizona, so I tend to shop with him first, because I encourage that level of commitment.

Garrett resells bits, including bits from Cody, and provides an active YouTube channel with demonstrations of CNCs and projects, which is why I also recommend him.

Bit #1: Amana 46102-K 1/4" Upcut Spiral Bit

- Specs: 1/4" diameter shank with 2 cutting flutes

- Chip Load: 0.006" per tooth in MDF, 0.005" in hardwood, such as maple

- RPM: 16,000. This is in the mid-range for both spindles and routers

MDF Calculation

- Chip Load = 0.006" per tooth

- RPM = 16,000

- Flutes = 2

- Feed Rate = 16,000 × 0.006 × 2 = 192 IPM

Really, 192 IPM? The Onefinity's rigidity can handle that without a problem. My entry-level CNC tops out at 110 IPM and my Journeyman tops out at 400 IPM, so you can get an idea of the difference in performance between the two. If your wood starts smoking or the machine squeals, back it down. Also, this should be adjusted depending on the depth of cut (DOC) you're making into the wood. Generally speaking, these numbers hold for a DOC equal to the diameter of the bit. So, if you're using a 1/4" diameter bit and your DOC is 1/4", this feed rate should work. If you're cutting deeper, reduce the feed rate, or increase the spindle RPM. Conversely, if your cut is shallower, you can increase the feed rate, or decrease the spindle RPM. There is a "sweet spot" for your spindle that you'll want to operate within. In my case, it's about 16,000 RPMs for my router. Spindles have a wider RPM range they can efficiently operate within, where routers are usually better above 1/2 of their Max RPM so they can maintain enough torque to work as needed.

Maple Calculation

- Chip Load = 0.005" per tooth

- RPM = 16,000

- Flutes = 2

- Feed Rate = 16,000 × 0.005 × 2 = 160 IPM

A sturdy 160 IPM, maple's density means a smaller chip load keeps things smooth. Your stepper motors will thank you.

Bit #2: Amana 46127-K 1/8" Upcut Spiral Bit

- Specs: 1/8" diameter shank with 2 cutting flutes

- Chip Load: 0.005" per tooth in MDF, 0.004" in hardwood, such as maple

- RPM: 16,000. This is in the mid-range for both spindles and routers

MDF Calculation

- Chip Load = 0.005" per tooth

- RPM = 16,000

- Flutes = 2

- Feed Rate = 16,000 × 0.005 × 2 = 160 IPM

A zippy 160 IPM, solid for this smaller bit in MDF (and equal to the larger bit in maple).

Maple Calculation

- Chip Load = 0.004" per tooth

- RPM = 16,000

- Flutes = 2

- Feed Rate = 16,000 × 0.004 × 2 = 128 IPM

At 128 IPM, it's still a respectable rate and precise, perfect for maple with this slim 1/8" bit.

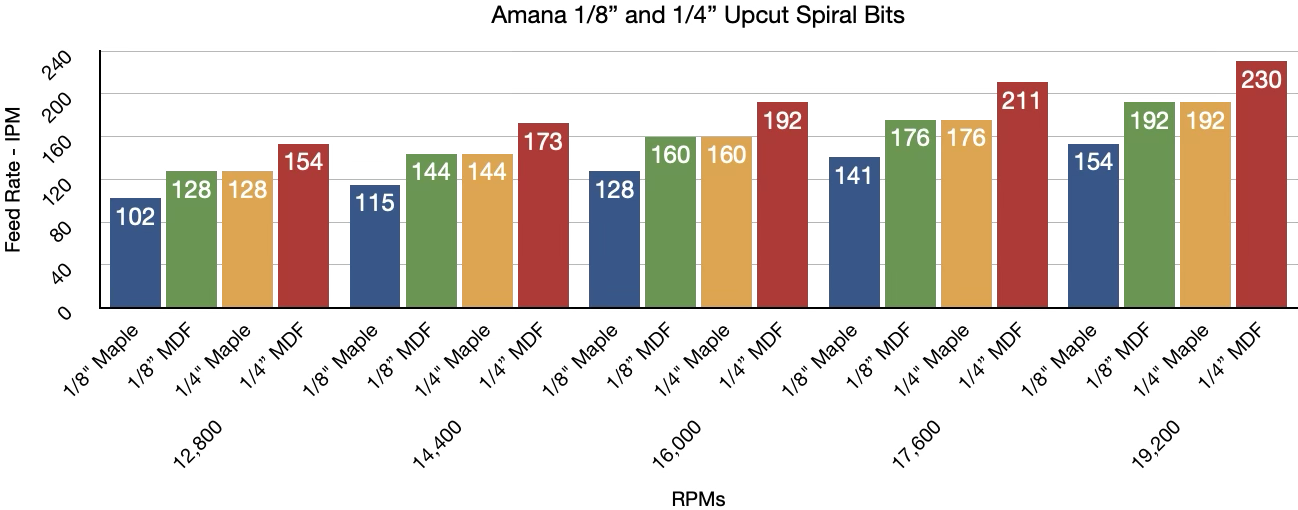

Seeing It in Action: Graph

Let's put these numbers on a column graph to see how feed rates stack up across our bit and material combos. I added in adjustments to the RPMs for 12,800 RPMs (20% slower), 14,400 (10% slower), the original 16,000, and RPMs of 17,600 (10% faster) and 19,200 (20% faster) for comparison.

The graph shows both the RPMs for the 1/8" and 1/4" bits, along with Maple and MDF woods for the X axis and the Feed Rate for the Y axis. No real surprises here, the CNC feed rates increase or decrease according to the RPMs of the spindle. And softer MDF allows faster feed rates than harder maple.

Trial Cuts: Test Before You Wreck

Numbers are a jumping-off point, but wood has its own mind and your CNC may be above or below my Journeyman used as a reference. Grab some scrap MDF and maple (or whatever hardwood scrap you have available), and run trial cuts with these settings. Start with the calculated feed rates (like 192 IPM for the 1/4" bit in MDF). Listen for chatter (that shaky rattle) or squealing (too much friction). Check the finish, burn marks mean you're moving too slow or spinning too fast; tear-out means you're too aggressive. Bump the feed rate up or down by 20–30 IPM until it feels right. Or, you can adjust your spindle speed, but keep that "sweet spot" in mind. This is where "guidelines, not exact" shines, you're tuning it to your setup.

Rookie Mistakes to Dodge

We've all botched a cut or two (or ten). Here's what to skip:

- Too High an RPM: Cranking it to 20,000 RPM might sound simple, but it can melt your bit into the wood (especially MDF) or snap a 1/8" bit. Also, for palm routers in particular, there is a lot more runout than with a spindle. Runout is an indication of slack or wobble of the spindle shaft, with more runout indicating more vibration. Stick to 16,000 for now.

- Too Slow a Feed Rate: Crawling at 50 IPM when you should be at 160 IPM builds heat, dulls your bit, and leaves burn marks. Keep it moving!

- Ignoring Bit Wear: A dull bit fights the wood, not cuts it. If you're getting dust instead of chips, swap it, maple's a bit-killer since it's hard. MDF typically only generates dust, so check on the heat of the bit, when it's not running, of course. You should be able to touch the bit without burning yourself after finishing a cut. It will almost certainly be warm, but it should not be a problem to touch it for a few seconds. If it's too hot, you could damage the bit's heat treatment, which softens the metal.

- Overloading the Spindle: Palm routers as spindles (common on entry- and hobby-level CNCs) can't handle deep cuts or fast feeds. They bog down or overheat. The Onefinity is sturdier, but don't push too far past its limit with a 1/4" bit in maple at 200+ IPM.

These slip-ups hit harder on entry-level machines, but even the Onefinity needs some love. Start with our graph, test, and tweak.

Wrapping It Up

I hope this intro to Chip Load and Feeds and Speeds was helpful. With the Onefinity Journeyman, you've got a hobby-level beast, but it's not an industrial tank. Kick off with our graph's numbers, run trial cuts, watch for trouble, and adjust. These formulas are your starting line, not your finish.

Next time you fire up your CNC, you'll feel less like you're guessing and more like you're in charge. Got a question or a cut gone wrong? Drop a comment, I'm here to help. Now, go make some chips (not dust) and turn that wood into something awesome!